Recently, the Astronomy and Space Mirror Technology Research Laboratory of Nanjing Institute of Astronomical Optics & Technology has completed the manufacturing of the 1.93-meter aspherical primary mirror for MOST(Muztage-Ata One-point-nine-three-meter Synergy Telescope).

MOST was jointly initiated by Academician Su Dingqiang, Academician Cui Xiangqun, and Professor He Xiangtao. It is co-built by Beijing Normal University, Xinjiang Astronomical Observatory of the Chinese Academy of Sciences, Nanjing Institute of Astronomical Optics & Technology, and Xinjiang University, with NIAOT responsible for its development.

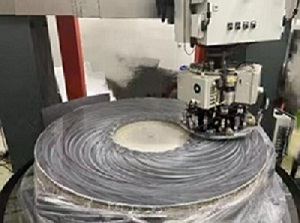

Both fine grinding and polishing of the primary mirror were accomplished using the active stressed lap, a technology pioneered domestically by the team of Academician Cui Xiangqun, which won the second prize of the National Science and Technology Progress Award.

The active stressed lap achieves real-time deformation controlled by a computer to match the required mirror surface shape, while optimizing various process parameters to achieve high-speed, high smoothness, and high surface shape accuracy in the processing of large mirrors. In just two months, RMS reached 0.8μm, demonstrating the continuous development of NIAOT in the active stressed lap technology over the past few years and achieving new improvements in the efficiency and accuracy of large mirror polishing.

The project team combines a six-axis industrial robot with The Swing arm profiler (CN202210679970.3), addressing the challenge of accuracy affected by turntable jitter error. This integration provides sub-micrometer measurement data for the fine grinding and coarse polishing stages of mirror manufacturing, seamlessly integrating with optical interferometric inspection. This method reduces the risk and time-consuming process of transporting large-diameter mirrors back and forth between processing and inspection locations, and significantly improves inspection efficiency.

The precision polishing, driven by a robot-operated parallel turntable planetary grinding tool (CN201710928500.5, CN202011136061.2, CN202130717539.X), achieved stable polishing characteristics through precise control of revolution, rotation, and polishing pressure.

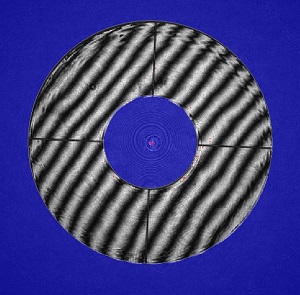

The independently developed process analysis software integrates detection data processing, dwell time calculation, and processing path generation, realizing digital automatic polishing, good determinism, and fast error convergence. The RMS value of the full aperture surface shape is better than 1/50 wavelength, surpassing the design specifications.The successful manufacturing g of the 1.93-meter primary mirror for MOST marks that NIAOT’s advanced technological processing and inspection methods, represented by the active stressed lap, the Swing Arm profiler, and parallel flat-rotating polishing tools, have entered routine use and reached a new level , and will play an irreplaceable role in the development of China's large and ultra-large astronomical optical telescopes.

Polish the 1.93-meter primary mirror using the active stressed lap

Swing arm profiler for mirror inspection

Parallel turntable planetary polishing tool for precision polishing

Mirror interference fringes