Recently, the Astronomy and Space Mirror Technology Laboratory of the Nanjing Institute of Astronomical Optics & Technology (NIAOT) completed the manufacturing of an aspherical mirror with the diameter of 2.5m. This mirror is the largest single mirror developed by the Institute so far. It is also another large aspherical mirror completed by the Institute in recent years, following the 2 meter annular primary mirror of the Yunnan Observatory solar telescope and the 1.6 meter primary mirror of the Yunnan University multi-channel telescope.

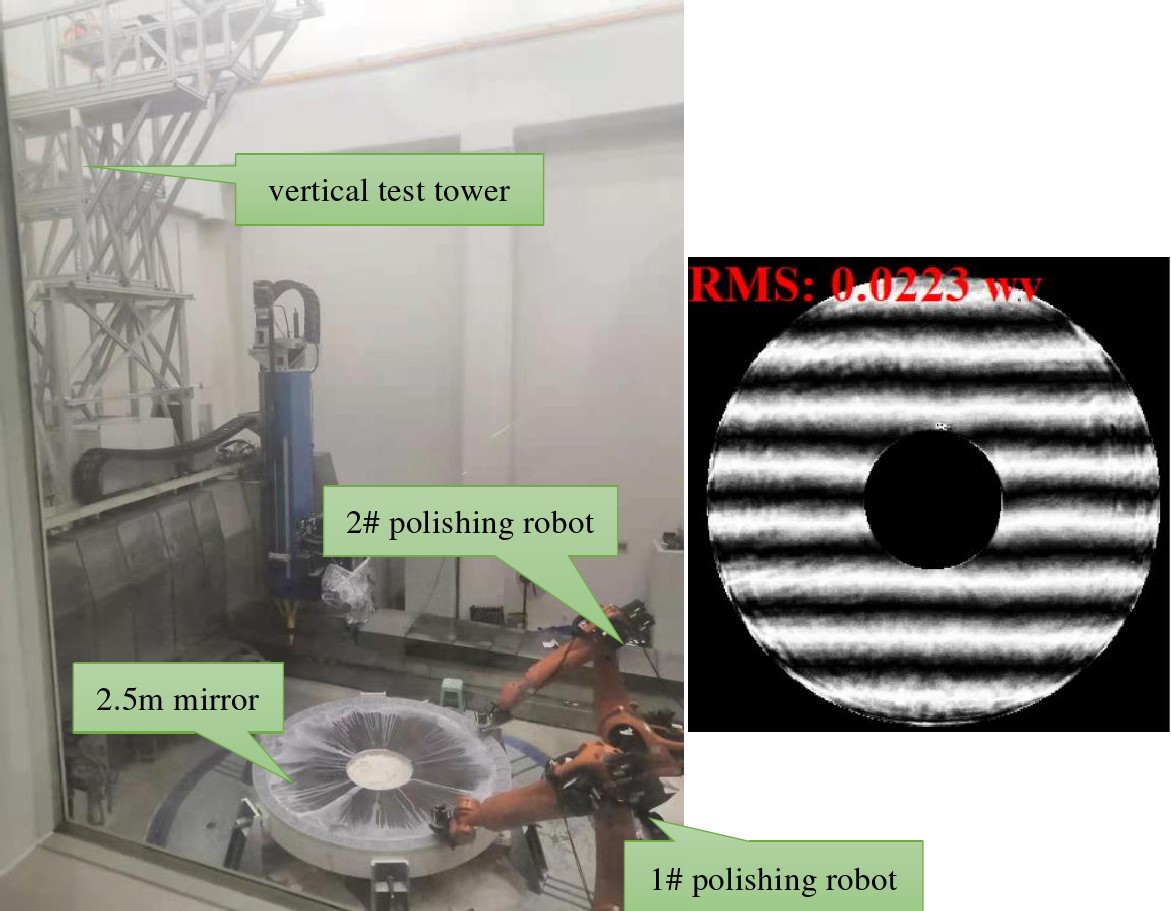

During the manufacturing of this mirror, the laboratory built a polishing/test integrated platform based on the vertical test tower and the 4m CNC machine, which can realize in-line mirror surface test. Many technical difficulties in the long optical path for large mirror surfaces have also been solved.

The mirror was polished by a dual robot polishing station independently developed by the laboratory. The group of computer controlled mirror polishing in the laboratory has independently carried out relevant research for many years, and has played a key role in many mirror processing tasks of various important projects undertaken by the institute. In order to deal with the oversize mirror with a diameter of 2.5 meters, based on the existing technology, the group has further developed the dual robot collaborative polishing technology and the small scale error local polishing technology, which have greatly improved the efficiency of the oversize mirror in the early and late stages of polishing respectively. The RMS value of the final surface accuracy of the 2.5 m aspheric mirror reaches 1/45 wavelength (i.e. 14 nm), which is better than its design target of 1/40 wavelength. Several invention patents (CN202110188942.7, CN202211212666.4, CN202211178684.5) have been applied for related technologies, and one of which has been authorized.

In addition, several optical workers of the laboratory successively participated in the project. They used the traditional experience advantages of the laboratory in optical processing to contribute to the completion of the mirror.

The successful manufacturing of this mirror, the earlier 2m primary mirror and the 1.6m primary mirror shows that the Institute has built a mature large aperture aspheric mirror manufacturing platform, which has the efficient development capability of 2.5m and larger mirrors. And the relevant manufacturing and testing technologies of the institute have reached the advanced level in China.

The 2.5m mirror manufacturing/testing platform (left) and the final test result of the mirror (right)

|